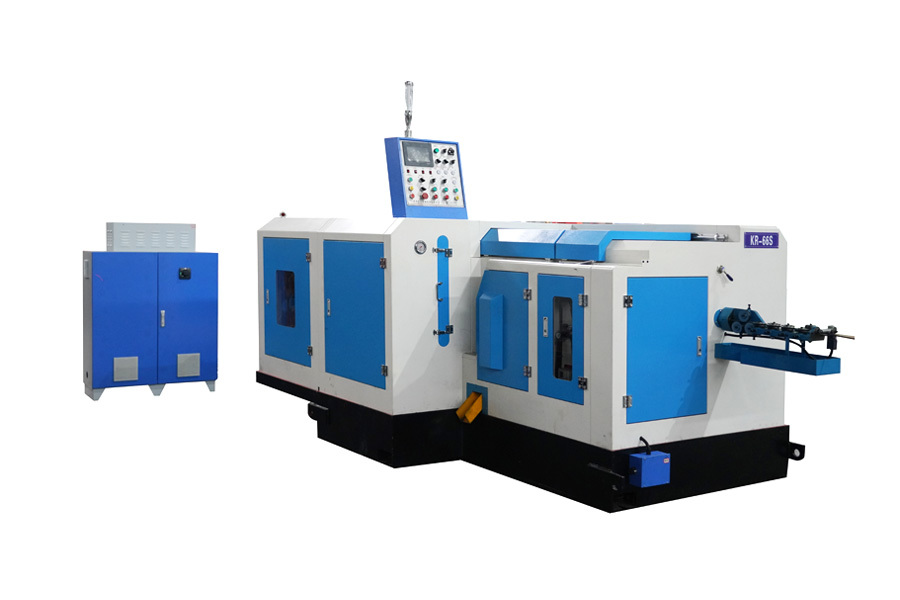

Corinille cold heading machine

Corey Neil cold heading machine is a kind of high production efficiency, large production range, suitable for complex deformation, set upsetting, extrusion, trimming in one of the molding machine. We never ignore any of the subtle links, determined to obtain each part of the processing accuracy, process are within the scope of our effective production control. Unlimited to improve the added value of users is our eternal goal, the company has been committed to providing users with high-efficiency, high-quality, cost-effective machinery and equipment, to help users continuously improve production efficiency, reduce costs, and ultimately enhance the user's market competitiveness. Fast, meticulous and comprehensive pre-sales and after-sales service is a powerful guarantee for us to continuously meet and overload customer needs. The needs of users are our needs.

|

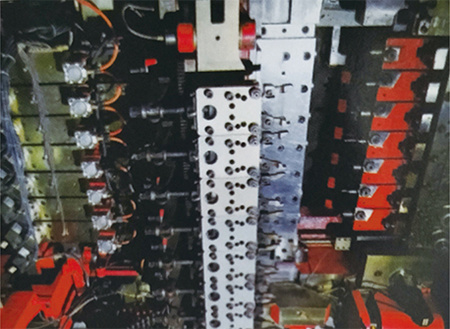

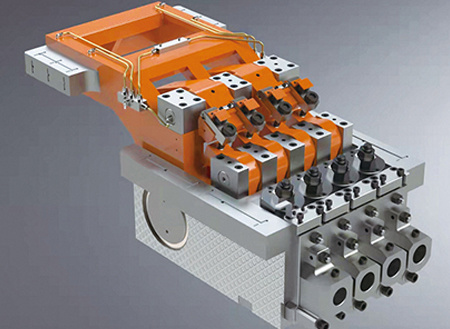

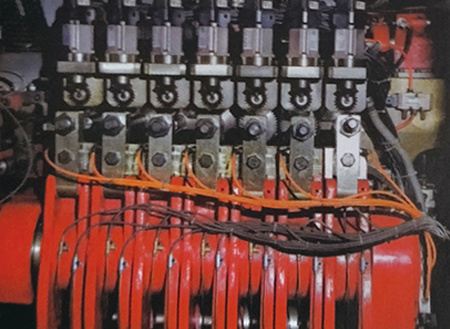

Pendulum pneumatic clamp: the clamping force can be adjusted according to the material properties of the product. When it is short, the first group of clamps will not be clamped automatically. The final clamp puts the finished product into the internal conveyor belt and is transported out by the internal conveyor belt to ensure the integrity of the finished part. |

The front and rear exit mechanisms are controlled by digital servo motors and can be set for remote debugging. Product debugging is convenient, finished product manufacturing precision is high. |

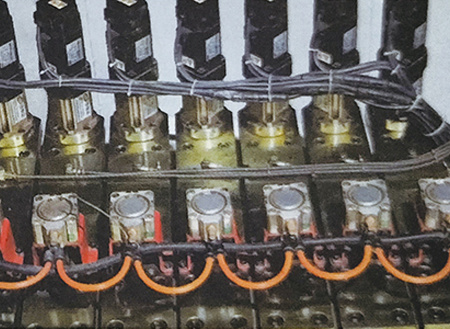

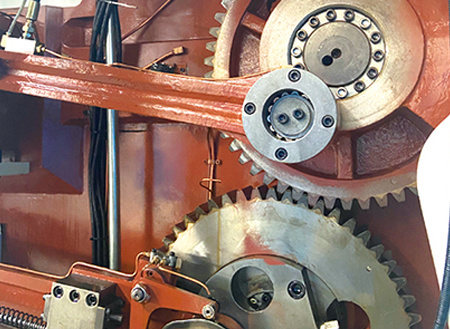

Clutch: pneumatic clutch and pneumatic brake to avoid repeated generation of starting current during equipment debugging, to facilitate parking and reversing, and to greatly improve mold debugging efficiency. |

Pneumatic clamping material can quickly adjust the clamping center, easy to operate, stable, can be arbitrarily changed turning clamping mechanism (optional) |

|

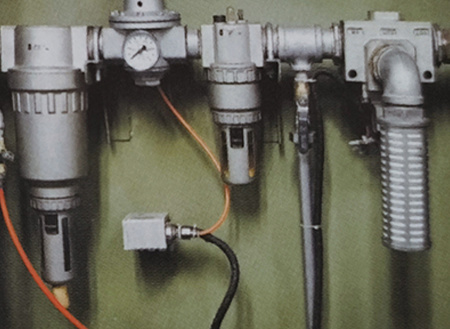

Centralized air pressure system with high configuration and easy adjustment. |

Accurate cutting mechanism, cutting force on the center of the spindle |

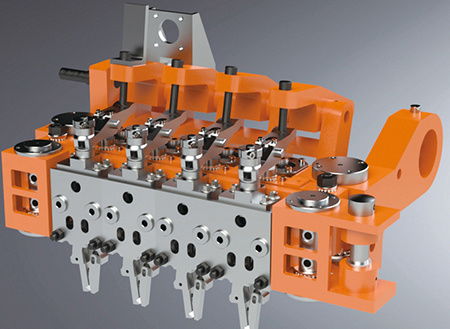

The high-precision main slider is connected with the rear wing design, which makes the main slider travel more stable and accurate. QT600 material is more wear-resistant and heat-resistant. The inner lining is applied with ZQsn10-1 thickened copper sleeve to ensure accuracy and prolong service life. |

Each station of the back-out mechanism can be adjusted independently, and the last station can realize the trimming action by adjusting the cam position or replacing the cam. Equipped with pressure detection safety pin. |

Five advantages of equipment

High utilization rate of steel

High production efficiency

high mechanical performance

Suitable for automated production

Widely applicable

Classification:

Key words:

Related Products

Product Consulting

Telephone

Hello, what can we do for you?