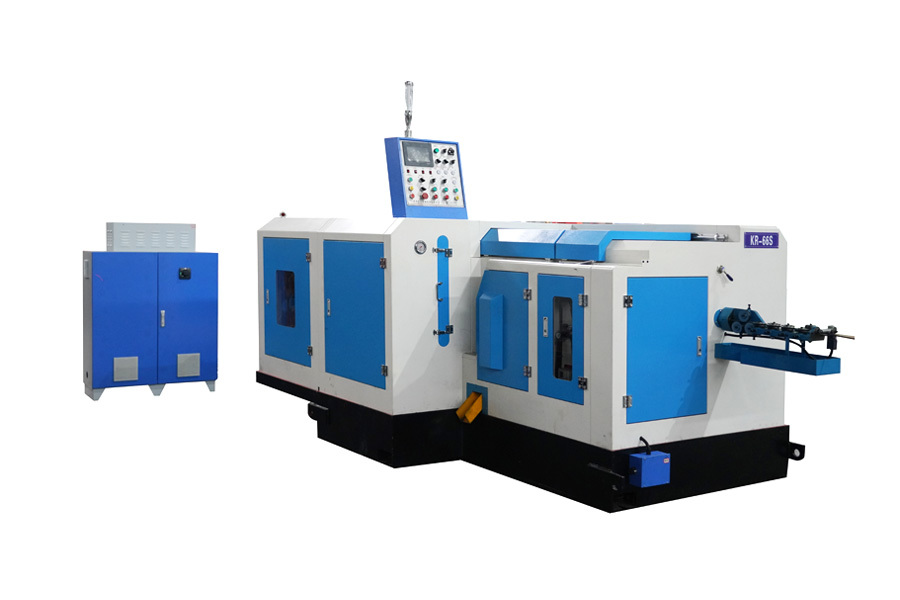

Four-die four-punch screw forming machine

It is widely used in the production of various fasteners and non-standard special-shaped parts in aviation, shipbuilding, automobiles, motorcycles, electric vehicles, mechanical basic parts and other industries. At the same time, it can produce non-standard molding machines according to the special requirements of users, and provide Professional services.

Unit: mm

|

Specifications |

STBF | STBF | STBF | STBF | STBF | STBF | STBF | STBF | STBF | STBF | STBF | STBF | STBF | STBF | ||

| Model | 10B4S | 10B4SL | 13B4S | 13B4SL | 13B4SXL | 13B4SUL | 17B4S | 17B4SL | 17B4SXL | 17BASUL | 19B4S | 19B4SL | 19BASXL | 19BSUL | ||

| Modulus | 4 | |||||||||||||||

| Maximum cutting diameter | 9 | 11 | 13 | 17 | ||||||||||||

| Maximum cutting length | 70 | 105 | 105 | 130 | 180 | 220 | 135 | 180 | 230 | 350 | 140 | 185 | 240 | 400 | ||

| Rear jack-out length | 60 | 90 | 90 | 120 | 175 | 215 | 115 | 175 | 225 | 325 | 120 | 180 | 225 | 325 | ||

| Front support jacking length | 13 | 20 | 20 | 23 | 30 | 34 | 20 | 30 | 36 | 60 | 26 | 30 | 35 | 60 | ||

| Cutting die | 28x46 | 28x46 | 28x46 | 35x56 | 38x79 | 38x79 | 40x66 | 40x80 | 40x80 | 40x80 | 46x80 | 46x80 | 60x100 | 65x100 | ||

| Mother model | 50x65 | 50x105 | 50x105 | 60x130 | 70x185 | 70x240 | 70x135 | 80x185 | 80x240 | 80x330 | 93x135 | 93x190 | 93x240 | 93x350 | ||

| Mother mold center distance | 60 | 87 | 93 | 114 | ||||||||||||

| male mode bundle | 40x80 | 40x110 | 40x110 | 45x110 | 45x130 | 45x175 | 50x111 | 50x130 | 50x190 | 50x200 | 60x120 | 60x170 | 60x200 | 60x250 | ||

| Main slide travel | 120 | 150 | 150 | 182 | 250 | 350 | 180 | 250 | 360 | 460 | 200 | 270 | 360 | 500 | ||

| Pressure (ton) | 40 | 40 | 65 | 65 | 70 | 70 | 85 | 85 | 90 | 90 | 120 | 120 | 130 | 130 | ||

| Products | Dimensions | 1/4( m6 ) | 5/16( m8 ) | 3/8 ( m10 ) | 1/2 ( m12) | |||||||||||

| Maximum length | 50 | 75 | 75 | 100 | 150 | 200 | 100 | 150 | 200 | 300 | 100 | 150 | 200 | 300 | ||

| The shortest length | External Hexagon Screw | 12 | 16 | 16 | 20 | 30 | 40 | 16 | 30 | 50 | 100 | 20 | 40 | 50 | 100 | |

| Powerful screw | 16 | 20 | 20 | 25 | 40 | 40 | 20 | 40 | 50 | 100 | 25 | 40 | 50 | 100 | ||

| Maximum capacity per minute (pcs/minute) | 300 | 240 | 240 | 200 | 180 | 140 | 200 | 175 | 110 | 80 | 170 | 125 | 100 | 80 | ||

| Main motor (HP) | 15 | 15 | 18.5 | 18.5 | 22 | 22 | 30 | 30 | 37 | 37 | 37 | 37 | 45 | 45 | ||

| Mechanical Weight (ton) | 8 | 10 | 12 | 13.5 | 15.5 |

19.5 |

16 | 19 | 24 | 29 | 23 | 27 | 32 | 39 | ||

|

Specifications |

STBF | STBF | STBF | STBF | STBF | STBF | STBF | STBF | STBF | STBF | STBF | STBF | STBF | STBF | ||

| Model | 24B4S | 24B4SL | 24B4SXL | 24B4SUL | 30B4S | 30B4SL | 30B4SUL | 33B4S | 36B4SS | 36B4S | 36BASL | 36B4SXL | 41B4S | 45B4S | ||

| Modulus | 4 | |||||||||||||||

| Maximum cutting diameter | 20 | 25 | 28 | 31 | 36 | 40 | ||||||||||

| Maximum cutting length | 185 | 270 | 320 | 400 | 270 | 320 | 400 | 300 | 220 | 320 | 370 | 460 | 400 | 450 | ||

| Rear jack-out length | 185 | 230 | 280 | 335 | 230 | 285 | 335 | 260 | 185 | 290 | 340 | 410 | 340 | 390 | ||

| Front support jacking length | 33 | 36 | 56 | 60 | 35 | 60 | 60 | 45 | 30 | 60 | 60 | 60 | 60 | 70 | ||

| Cutting die | 60x100 | 60x120 | 75x120 | 84x130 | 90x140 | 110x140 | 115x140 | |||||||||

| Mother model | 100x195 | 100x240 | 100x294 | 100x360 | 125x240 | 125x94 | 125x360 | 145x280 | 160x210 | 160x294 | 160x370 | 160x450 | 178x385 | 195x420 | ||

| Mother mold center distance | 126 | 138 | 156 | 174 | 195 | 210 | ||||||||||

| male mode bundle | 75x160 | 75x200 | 75x232 | 75x232 | 90x190 | 90x232 | 90x240 | 96x210 | 105x180 | 105x232 | 105x235 | 106x270 | 120x250 | 135x280 | ||

| Main slide travel | 280 | 360 | 420 | 500 | 360 | 430 | 500 | 400 | 300 | 440 | 500 | 600 | 500 | 580 | ||

| Pressure (ton) | 200 | 200 | 215 | 215 | 265 | 285 | 300 | 320 | 360 | 380 | 420 | 450 | 520 | 635 | ||

| Products | Dimensions | 5/8( m16 ) | 3/4 ( m20 ) | 7/8( m22 ) | 1 ( m24 ) | 1-1/8 ( m27 ) | 1-3/4( m30 ) | |||||||||

| Maximum length | 150 | 200 | 250 | 300 | 200 | 250 | 305 | 225 | 150 | 250 | 300 | 380 | 300 | 355 | ||

| The shortest length | External Hexagon Screw | 25 | 50 | 60 | 100 | 40 | 60 | 100 | 50 | 40 | 60 | 100 | 100 | 100 | 100 | |

| Powerful screw | 35 | 50 | 60 | 100 | 40 | 60 | 100 | 60 | 50 | 60 | 100 | 100 | 100 | 100 | ||

| Maximum capacity per minute (pcs/minute) | 120 | 100 | 75 | 65 | 90 | 65 | 60 | 80 | 80 | 60 | 55 | 45-50 | 45 | 40-45 | ||

| Main motor (HP) | 55 | 55 | 55 | 75 | 75 | 75 | 90 | 90 | 90 | 90 | 110 | 110 | 132 | 132 | ||

| Mechanical Weight (ton) | 45 | 51 | 56 | 62 | 65 | 76 | 87 | 85 | 86 | 108 | 128 | 160 | 152 | 195 | ||

Remarks:

1. The company at any time to study and improve the work, so the right to change the design, size and mechanical structure specifications at any time, this catalog specifications are for reference only;

2. Equipment capacity varies according to the shape, material and tensile strength of the wire;

3. The data in parentheses of the back support ejection length indicates the longest length of the inverted product during the pressing process.

Five advantages of equipment

High utilization rate of steel

High production efficiency

high mechanical performance

Suitable for automated production

Widely applicable

Classification:

Key words:

Related Products

Product Consulting

Telephone

Hello, what can we do for you?