Corey Neil Machinery

Key words:

Corinille cold heading machine

Corey Neil cold heading machine is a kind of high production efficiency, large production range, suitable for complex deformation, set upsetting, extrusion, trimming in one of the molding machine. We never ignore any of the subtle links, determined to obtain each part of the processing accuracy, process are within the scope of our effective production control.

Key words:

Three-mold three-punch screw forming machine

Corinille cold Chin machine is a kind of high production efficiency, a larger production range, suitable for complex deformation, set Qin forging, extrusion, trimming in one of the molding machine. We never ignore any of the subtle links, determined to obtain each part of the processing accuracy, process are within the scope of our effective production control.

Key words:

Four-die four-punch screw forming machine

It is widely used in the production of various fasteners and non-standard special-shaped parts in aviation, shipbuilding, automobiles, motorcycles, electric vehicles, mechanical basic parts and other industries. At the same time, it can produce non-standard molding machines according to the special requirements of users, and provide Professional services.

Key words:

Five-die five-punch screw forming machine

It is widely used in the production of various fasteners and non-standard special-shaped parts in aviation, shipbuilding, automobiles, motorcycles, electric vehicles, mechanical basic parts and other industries. At the same time, it can produce non-standard molding machines according to the special requirements of users, and provide Professional services.

Key words:

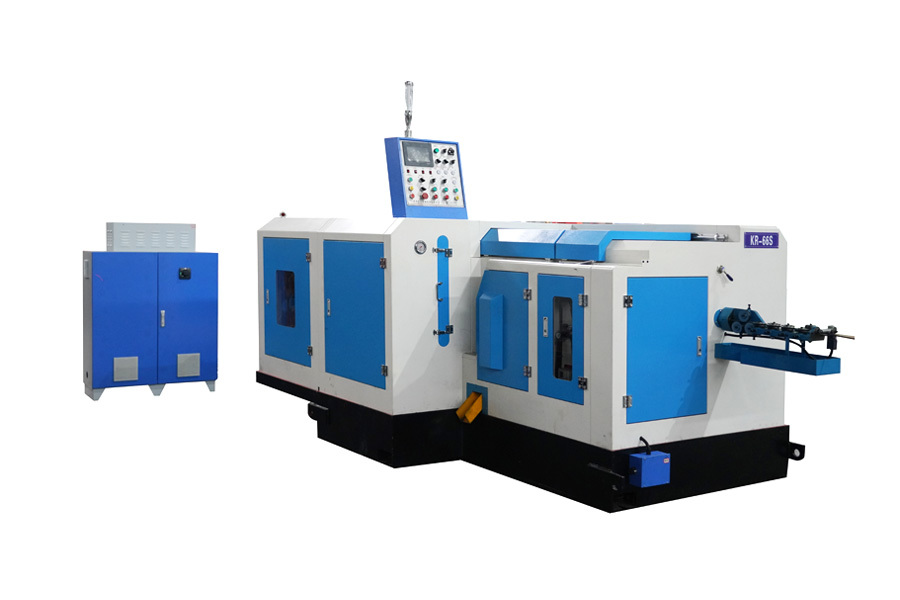

Six-die six-punch screw forming machine

It is widely used in the production of various fasteners and non-standard special-shaped parts in aviation, shipbuilding, automobiles, motorcycles, electric vehicles, mechanical basic parts and other industries. At the same time, it can produce non-standard molding machines according to the special requirements of users, and provide Professional services.

Key words:

Seven-die seven-punch screw forming machine

It is widely used in the production of various fasteners and non-standard special-shaped parts in aviation, shipbuilding, automobiles, motorcycles, electric vehicles, mechanical basic parts and other industries. At the same time, it can produce non-standard molding machines according to the special requirements of users, and provide Professional services.

Key words:

Eight die eight punch screw forming machine

It is widely used in the production of various fasteners and non-standard special-shaped parts in aviation, shipbuilding, automobiles, motorcycles, electric vehicles, mechanical basic parts and other industries. At the same time, it can produce non-standard molding machines according to the special requirements of users, and provide Professional services.

Key words:

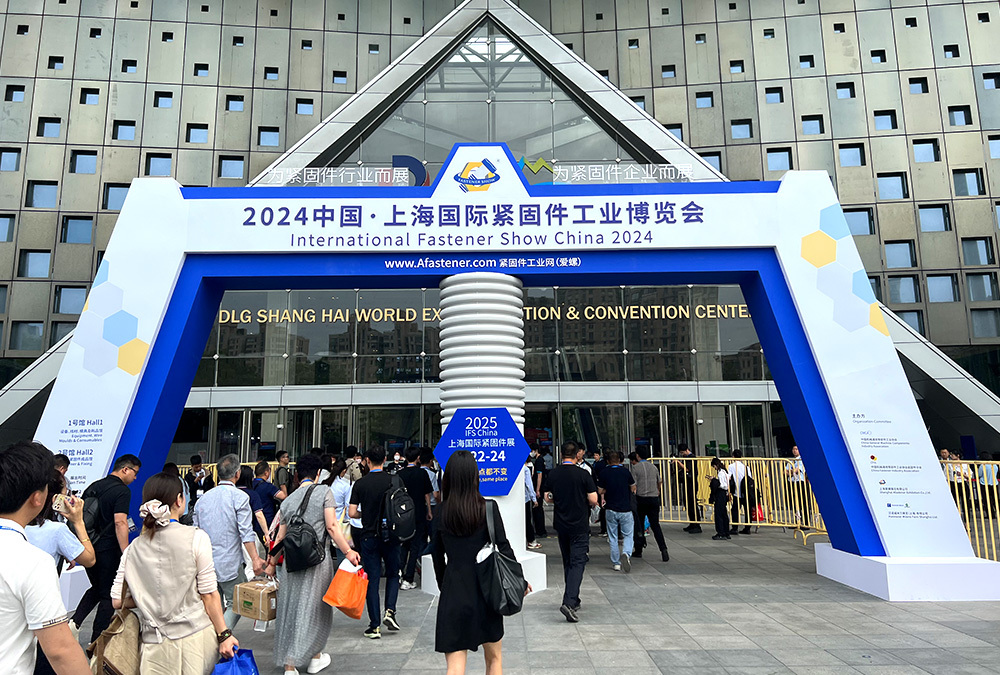

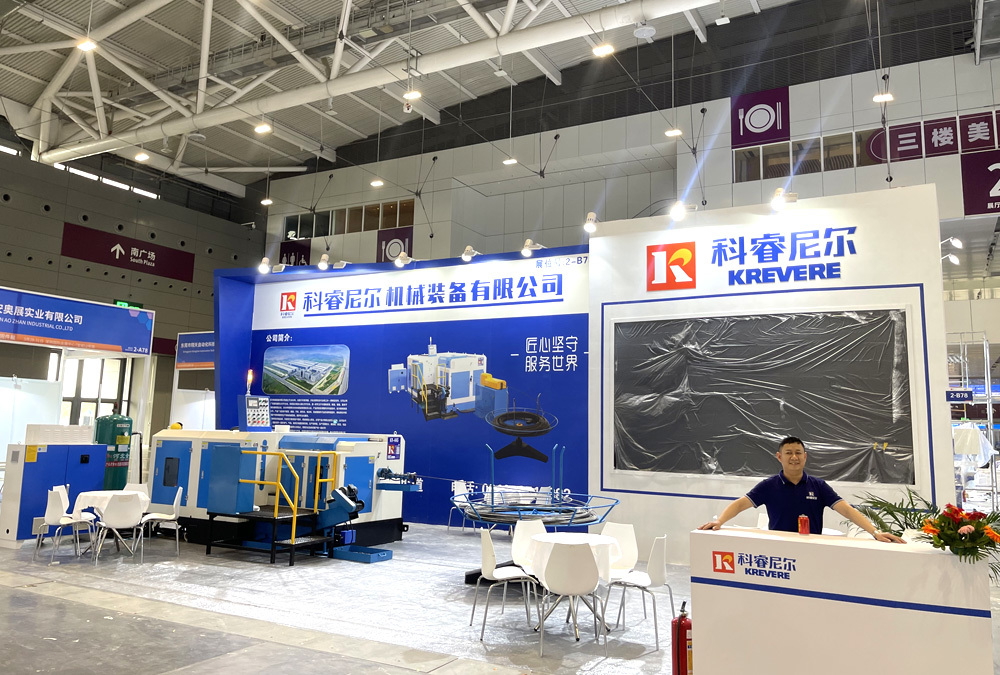

Corey Neil Attends 2024 China Shanghai International Fastener Industry Expo

Corinille participated in the China Shanghai International Fastener Industry Expo 2024 to showcase its innovative achievements and advanced technologies in the field of fasteners.

Key words:

Pakistan customers to the factory to buy equipment

Recently, our factory welcomed a group of special guests-customers from Pakistan. The purpose of their visit is to personally purchase a batch of production equipment.

Key words:

Corey Neil Attends 2024 Shenzhen International Fastener Exhibition with Full Harvest

With the rapid development of the global manufacturing industry, the fastener industry, as an important part of it, has also ushered in new development opportunities. In order to further strengthen exchanges and cooperation with global counterparts, we will participate in the international fastener exhibition to be held in Shenzhen in 2024.

Key words:

Our company held a grand annual commendation meeting

Today, we gather here to celebrate a year of hard work and brilliant achievements and hold this grand annual commendation meeting.

Key words:

Cold pier machine wire need phosphating?

Phosphating treatment is a very important process for cold pier wire. This is because phosphating treatment can effectively improve the anti-rust performance of the wire, prevent the wire from oxidizing and rusting during storage and transportation, and also enhance the adhesion between the wire and quenching, making the final mechanical properties of the wire better.

Key words:

What is the difference between cold heading and hot heading?

A forging process in which the top of a bar or wire is thickened at room temperature. Cold heading is mainly used in the manufacture of bolts, nuts, nails, rivets and steel balls and other parts. The forging blank material can be copper, aluminum, carbon steel, alloy steel, stainless steel and titanium alloy, etc., and the material utilization rate can reach 80-90%.

Key words:

Use and characteristics of cold pier machine

1. Inlaid oil-free self-lubricating bearings can improve the life and wear resistance of the coupling shaft and reduce energy consumption. 2. The circuit system is frequency converter plus PLC, which can not only continuously change speed, but also automatically detect the fault state of the machine to stop.

Key words:

What does the cold heading machine do and what should be paid attention to in operation

Cold heading machine is a kind of metal processing equipment, which is mainly used to make various specifications of fasteners, such as bolts, nuts, screws, rivets, etc., from metal bars through cold working methods.

Key words:

Overview of common models of cold heading machine

This machine adopts plate material and straight bar material, using the principle of secondary upsetting and forging, to produce all kinds of yuan head, countersunk head, semi-countersunk head, hexagon socket and other non-standard head-shaped bolts and mechanical parts, the equipment is easy to operate, simple process, and can be set as a positive mold to push out slender specifications of the protection device and pull-out mechanism.

Key words:

Selection and operation precautions of multi-station cold heading machine

In the selection and operation of multi-station cold heading machine, the correct selection and operation method is very important for the processing quality and efficiency. The following are several selection and operation considerations that need attention:

Key words:

The working principle and application range of high-speed cold heading machine

High-speed cold heading machine is a kind of machinery and equipment widely used in metal processing industry, which is mainly used for cold deformation processing of metal wire. It has been widely used in various machinery manufacturing, automobile manufacturing, aerospace and other industries. Let's take a look at the working principle and application scope of high-speed cold heading machine.

Key words:

Cold heading machine is a kind of equipment used for cold heading of metal materials, which has a complex structure and contains a number of key components.

Key words:

What kind of cold extrusion process is used in the process of cold heading machine

Cold heading machine is a kind of mechanical equipment for metal processing, which uses cold extrusion process to process metal materials. The basic principle of the cold extrusion process is to apply axial force to the metal material at room temperature, and change the cross-sectional shape and size of the metal material by extrusion. The following are the general steps of the cold extrusion process in the cold heading machine processing process:

Key words:

Multi-station cold heading machine is a kind of equipment used for metal processing. It is usually used to complete multiple cold heading processes on one machine. It has the characteristics of accuracy and high efficiency. Its use with other metal processing equipment and production line synergy can bring the following benefits:

Key words:

Don't know how to choose the best for yourself?

Let us assist you!

Our experts will contact you within 24 hours to meet your needs.

Products

News

Telephone

Hello, what can we do for you?